Top warehouse tech trending in the Middle East and Africa in 2020

It’s that time of year again. As we’re about to enter 2020, we’re looking back at how this year’s trends compared to our predictions as well as what we can look forward to in the supply chain industry in the new year.

At the beginning of the year, we shared our predictions for Supply chain trends for 2018. The main takeaway from this article is that 2019 would be marked by a strong focus on profitability, efficiency, and streamlining to mitigate excessively high warehousing costs in uncertain economies.

We predicted that businesses would see the following trends in their warehouses:

- A heavier focus on “right-sizing” inventory holdings

- The rise and continued adoption of Omni Channel

- The need to prepare for AI (artificial intelligence), automation and IoT (the internet of things)

Now, as we approach 2020, businesses in the Middle East and Africa (MEA) can expect to enjoy a number of new technologies, new developments, and cost-saving tools.

Challenges MEA businesses will face in 2019

The two main challenges faced by MEA businesses in 2020, as in 2019, will be the continued rising cost of operations, labour productivity, and skilled labour availability.

1. The rising cost of warehouse operations

New cost increases in South Africa, Saudi Arabia and the United Arab Emirates (UAE) in 2020 follow the same pattern as they did in 2019: increased fuel costs and increased VAT, where already-tight budgets are looking to become even tighter.

Why MEA businesses need to benchmark against world class best practices

It’s crucial for MEA businesses to benchmark their operations against world class best practices. This helps to ensure that you’re using the latest technology and processes to streamline your warehouse operations, for greater productivity and profitability.

The right warehouse management system (WMS) will help you to optimise areas such as your warehouse layout, picking process, inventory accuracy and visibility in your warehouse. By optimising your warehouse operations on an on-going basis, you’ll be able to pick up any bleeding points before they become a major problem.

2. Warehouse labour productivity and skilled availability

Secondly, labour productivity and skilled availability is always a challenge in these regions. One our customers in Saudi Arabia, for example, recently had to travel to India and the Philippines to recruit warehouse workers. Warehouse automation, however, offers a viable solution.

Supply chain and WMS trends for 2020

There continues to be a heavy focus on increasing customer service, doing more with less (improving labour productivity, visibility and so on) and reducing reliance on multiple vendors, controlling various systems that run the warehouse.

While 2019 was the year for implementing and leveraging automation and machine learning, to improve accuracy, decrease costs and continue to increase productivity and flexibility, 2020 will take us deeper into the omnichannel rabbit hole, with demands on our multi-channel systems to become more flexible, more accurate, and more time-sensitive.

Omnichannel, whether in retail, wholesale or another industry vertical, is swiftly becoming ubiquitous to best-in-class Warehouse Managememnt.

In order to achieve success, supply chain facilitation is critical.

Your KPIs will need to reflect this drive, so an understanding of what kind of steps you'll need to take must be mirrored in your KPIs.

1. Omnichannel Sales, Omnichannel Satisfaction:

Without satisfied customers in this competitive environment, your business is guaranteed to fail. We now have many more platforms on which we can stuff up the relationship, and 2020 is the year to ensure that this is only a minor threat. How?

Manhattan’s Active Omni Solutions journey was born over a decade ago as a result of the requirement of major retail customers to secure a way to sell their entire pool of inventory from multiple distribution centers and then stored in our current native cloud solution.

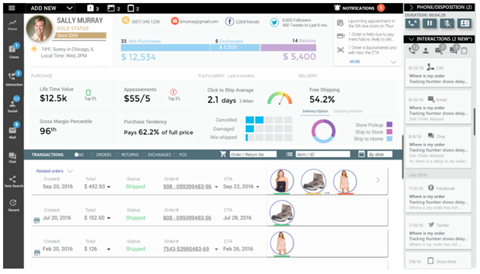

Recently enhanced with a customer engagement module, Manhattan’s Active Omni solution provides a single view of all customer purchases, interactions and service requests, regardless of which channel they were enacted via.

As an example, the Foschini Group employed a solution was to enable any DC to flow any brand through it and to review the placement of those DC’s so as to ensure they were close to the markets they served, thus reducing risk.

2. Smart Warehouse Technologies

Machine learning capabilities are an important feature of modern WMS technologies, as it allows your software to self-modify.

The ARC Advisory Group writes:

“Self-modification, with its ability to adapt to changing situations, is good for dynamic data sets, where the relationship between the dependent and independent variables is fluid. When the predictive power of an algorithm changes, machine learning can recognize this degradation and create a new input-output relation, offering more robust predictive power. Machine learning’s ability to adapt to changing conditions makes it a particularly good fit for today’s e-commerce warehouses, where new orders are continually introduced into the existing workload. Waveless warehouse operations are a strong fit for machine learning.”

The Manhattan WMS has extended its solution to AI and machine learning in its order streaming solution, with “Enhanced Order Streaming Capabilities: to ensure optimised use of man and machine in the distribution center”.

3. Innovation through simplification

Innovation is no longer about building, adding, increasing technology. Innovation now focuses on an ascetic slimming-down of processes, hardware, software, users, and expenses.

Innovations in both WMOS and Manhattan SCALE include a WMS and WES in a single application from Manhattan Associates, your distribution center gains a single point of coordination of all DC resources and equipment

4. A strong focus on usability

There seems to be a strong move away from fancy, behemoth technologies which require a degree in rocket science to initiate. That's why Manhattan and SCJ have teamed up to create something simpler and more effective:

With the release of modernised interfaces in the WMOS and Manhattan Scale solutions, the usability and functionality is enhanced. This means that training time is reduced, and visibility is extended to provide more conclusive, useful insights.

"Simplify, extend, and improve" is the mantra for 2020. Start now!

Want to enhance your warehouse processes? Supply Chain Junction offers world class WMS solutions, available in the Middle East and South Africa. Contact us today to discuss your WMS requirements.

See how you can get started by referencing Tarsus Distribution's success:

TAGS

- WMS (51)

- Warehouse Best Practice (46)

- Implementing a WMS (29)

- Managing your warehouse (19)

- Omni Channel (18)

- eCommerce (18)

- Blog (16)

- Supply Chain Best Practice (16)

- Customer Journey (9)

- Mid-Level (8)

- Warehouse optimisation (7)

- General Tips (5)

- Industry General (5)

- Information (5)

- Trends (5)

- managing your Supply Chain (5)

- saudi arabia (5)

- Press Release (4)

- smart warehouse (4)

- 3PL (3)

- News (3)

- ERP (2)

- Entry-level (2)

- ROI (2)

- Case Study (1)

- OMS (1)

- Picking (1)

- Solution-Specific (1)

- Transport Management System (1)

Take A Look At The Results Of A Successful WMS Implementation.

See how Tarsus Distribution, in collaboration with SCJ boost overall efficiency by 60%