The top 5 smart warehouse technologies you should be using today

Technology in all sectors of the economy is progressing at a rapid pace. To keep up, warehouses need to be equipped with the technologies that allow them to keep up with manufacture, production, and consumer demand. A smart warehouse is automated for improved productivity, efficiency, and accuracy, and the solutions that are implemented give flexibility and capability to the employees and their processes.

Take a look at the technologies you should be using in your smart warehouse, with discussion on how to keep them flexible, functional, and effective.

Why should you automate your warehouse?

In addition to a reduction in human error, lower risk of injury, and the optimisation of throughput, your automation reduces your overheads, adds flexibility to your hours of operation, and allows you to be more accurate in assessing your workforce requirement.

There are a number of popular tools and products available, and you should be using the most prominent of these in your day-to-day operations, integrated for improved performance.

Supply Chain Junction’s Top 5 Must-Have Smart Warehouse Technologies

In no specific order, these are the five technologies you need access to in your warehouse today:

1. A Warehouse Management System

A WMS should comprehensively consolidate all of your critical warehouse data into one easily accessible platform, to give select members of your supply chain a full view of your workings, lightning-fast reporting, real-time statistics, and accurate planning capabilities.

The use of your warehouse management system should perfectly complement your other autonomous processes, and provide the following benefits:

- Real-time access to quality data giving you increased visibility throughout your supply chain

- Accurate demand forecasting

- Reduced labour costs due to efficient labour allocation

- Streamlined warehouse processes

- Optimised warehouse layout

- Improved inventory accuracy

- Improved pick accuracy

- Decreased time between picks

- Improved warehouse flexibility and responsiveness

- Improved warehouse safety and security

- Improved supplier relationships

- Improved customer service levels

- The ability to implement an ongoing optimisation strategy

2. Automated Picking Tools

We’ve worked with several companies who progressed through the stages of pick technology evolution - from paper to RF - and seen huge productivity and accuracy improvements.

In high-volume, high-labour cost distribution centres, picking is either performed or aided by using material handling equipment like put-to-light, automated storage and retrieval systems (ASRS), and goods-to-man.

Your warehouse can benefit from near-perfect picking rates with the inclusion of automated picking elements into your warehouse. There are a variety of different tools within this grouping, (like voice automated picking and pick-to-light) but remember: your WMS is designed to streamline your warehouse operations.

It improves picking by making it faster, improving labour allocation and reducing human error.

Instead of manually having to calculate the best locations, storage media, and pick paths for stock, your WMS does all the heavy lifting for you.

3. Automated Guided Vehicles

AGVs are an efficient mechanism of ramping up your storage and retrieval process, in putaway, loading, and stocktake. AGVs are self-guided and can include forklifts and pallet carts, which follow digital paths through the facility to load and unload pallets, boxes, and other containers.

These vehicles can be implemented in your warehouse without a complete revisiting of your layout and systems, with the ability to add and expand your AGV complement as required, in line with the growth of your business.

4. Automated inventory control platforms

What do you rely on for inventory logging, cycle counting, and stock take? If you are still using pen and paper for these processes, you are not alone: Motorola reported in 2018 that 41% of warehouse facilities still relied on this manual cycle-counting process.

This method, while tried and tested, is notoriously prone to errors in data, transcription, and consistency, and can cause immense disruption in your operations.

When you implement an inventory control platform with the requisite use of asset and inventory tags, these platforms allow you to automate stock counting, with data synthesised quickly for real-time, accurate reporting that can be accessed remotely.

5. IoT Implementation

The Internet of Things is the overarching concept (not an individual item) that informs how you control all the moving parts of your warehouse.

The IoT can help your warehouse to reduce risk and avoid mistakes or accidents that can create losses in the supply chain by early detection.

- Sensors in the warehouse can monitor temperature, moisture, and other conditions.

- Data coming from shipping conveyances, vehicles, and the products themselves can be combined to reduce theft, counterfeiting, diversion, and spoilage.

Whether automated or manual, the IoT system synchronises all of your data in an easy-to-access network, helping to optimise your inventory control (with double the impact if integrated with an automated inventory control platform), labour planning, and customer experience (through streamlined processes and improved turnaround time).

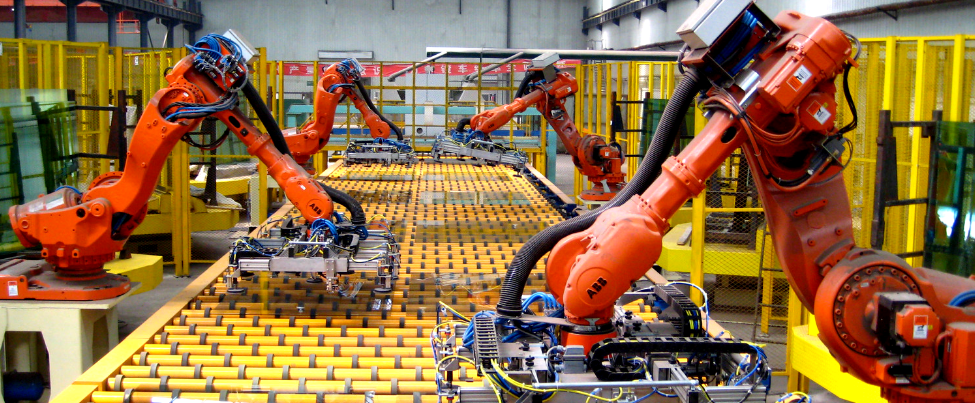

A step further with autonomous warehouse systems: Collaborative Robots

“Cobots” are fully autonomous and robotic technologies which require a sizable investment and infrastructure overhaul but are a VERY nice-to-have addition to a busy warehouse. Cobots are built to work with your existing associates, not without them.

Warehouses using these technologies can often keep most of their existing processes and infrastructure designs while benefiting from the optimised workflow that is achieved with this robotics.

Your integrated, automated warehouse processes could be also be supplemented with a number of robotic technologies, integrated with Materials Handling Units - like Automated Storage and Retrieval systems, which, in the past, have been clunky and ineffective, but are now becoming sleeker and more efficient.

Where to begin the warehouse optimisation process?

Now that your wish-list is full, and your long-term plans are coming into view, it’s best to start off with the simpler processes which help to streamline your operations:

This practical guidebook contains tips from our supply chain experts to help you implement processes that support your business goals and help you to develop a world-class warehouse.

TAGS

- WMS (51)

- Warehouse Best Practice (46)

- Implementing a WMS (29)

- Managing your warehouse (19)

- Omni Channel (18)

- eCommerce (18)

- Blog (16)

- Supply Chain Best Practice (16)

- Customer Journey (9)

- Mid-Level (8)

- Warehouse optimisation (7)

- General Tips (5)

- Industry General (5)

- Information (5)

- Trends (5)

- managing your Supply Chain (5)

- saudi arabia (5)

- Press Release (4)

- smart warehouse (4)

- 3PL (3)

- News (3)

- ERP (2)

- Entry-level (2)

- ROI (2)

- Case Study (1)

- OMS (1)

- Picking (1)

- Solution-Specific (1)

- Transport Management System (1)

Take A Look At The Results Of A Successful WMS Implementation.

See how Tarsus Distribution, in collaboration with SCJ boost overall efficiency by 60%