Saudi Arabian Warehouse Management Plans & Strategies for 2021

The future is always uncertain, but perhaps now more than ever. A global pandemic has simultaneously battered the supply-chain industry, re-emphasised its importance, and created entirely new goals and outlooks for years to come.

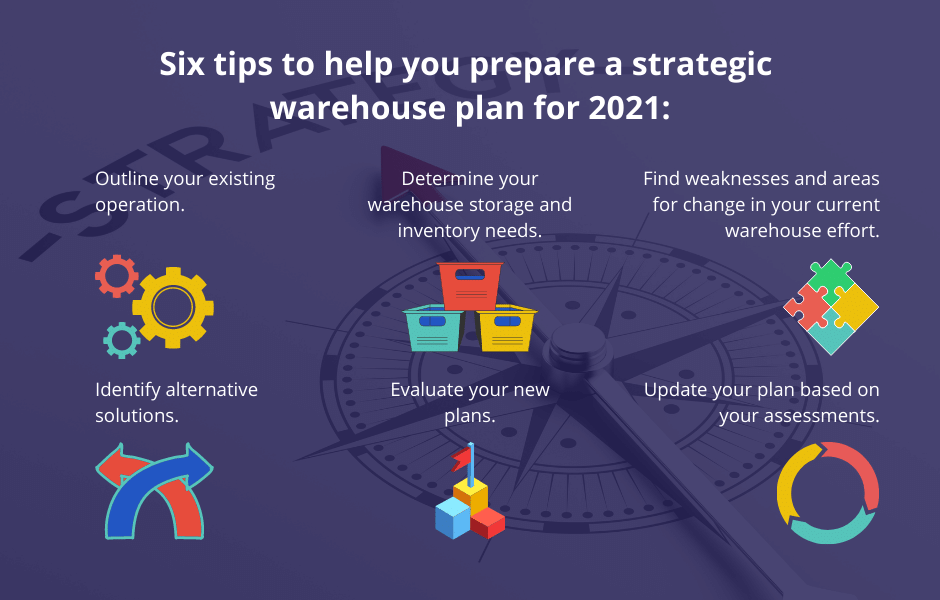

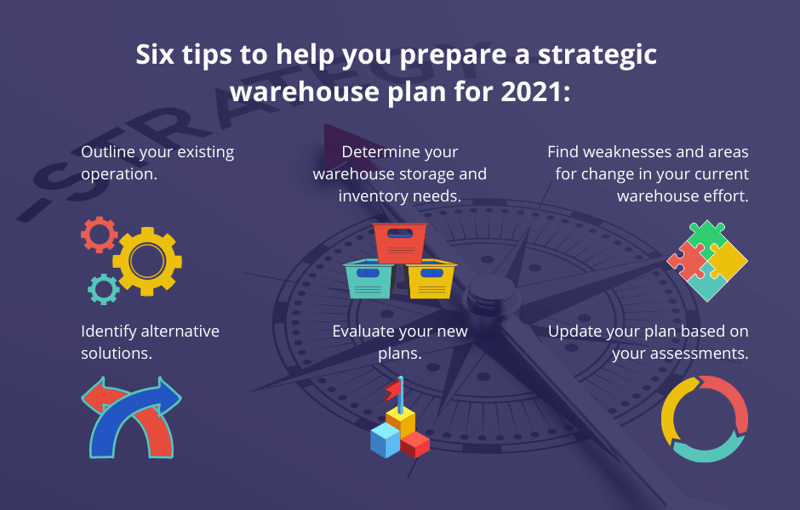

The warehouse operation plays a significant role in the advancement of any company. It is important that warehouses employ strategy to ensure an efficient operation and ultimately business success. Your strategy should involve many important decisions, such as the investment and operation costs that make up the logistics overhead, especially for you to be able to know what you need for where you plan on going.

Consider: the top warehouse challenges in Saudi Arabia at the moment

Here are the warehousing trends to count on in Saudi Arabia in 2021:

1. Stronger AI

Automation has been a trend in almost all industries since the previous decade. The continued success indicates that this trend will only get stronger in the coming year. Most notably, artificial intelligence (AI) has emerged as the primary propellant for automation in the supply-chain industry. By crunching data from past operations, AI algorithms can perform basic operations automatically. This saves a large amount of time and eliminates the possibility of human error, thus making the operations more efficient. It also redirects the human capital to perform more complex tasks.

INCREASE EFFICIENCY, SAVE MONEY - The potential of AI is, however, much more. AI can be used to identify patterns in data and bring useful insights. This could be used, for instance, to forecast demand in the near future. With the help of AI, operations within the supply chain can become more efficient and accurate.

2. End-to-end IoT

The internet of things (IoT) is another technology rapidly adopted by the supply-chain industry apart from blockchain. Like blockchain, IoT works in the direction of boosting transparency across the supply chain. GPS sensors can be fitted in modes of transportation like trucks to offer live location tracking. Sensors in the warehouse help visibility in inventory management, while those in retail outlets help in gauging demand.

STREAMLINE PROCESSES, IMPROVE TRANSPARENCY - The appealing factor of IoT is how easily it can be used within the entire supply chain, from beginning to end. The results from it allow companies to increase efficiency, minimise downtime, proactively respond to customer demands, and increase overall ROI.

3. Robotic automation

Automation in SCM is not limited to just the operations, but the manual tasks as well. The first two quarters of 2019 saw an investment of $869 million on robotic automation in North America alone. On the transportation end, drones are beginning to be used for delivering light-weight goods. Driverless vehicles are not yet a reality, but it might become one soon.

DRIVE PRODUCTIVITY - Within the warehouses, autonomous mobile robots (AMRs) can see wider acceptance for performing labour-intensive tasks. However, let’s dispel the oft-used fear: robots will not replace humans. In most supply chains, robots would only free human capital from menial labour, allowing them to focus on more important decision-making.

4. Smart contracts

The tides of automation will only keep rising in 2021, but on more than one wave. Beyond AI and robotics, smart contracts have emerged as another brilliant technology to achieve automation.

Smart contracts are transaction protocols that are meant to execute when certain conditions are met automatically. In the supply chain, it could mean automatically generating an invoice when the shipment reaches the destination or conducting financial transactions between parties.

FUTURE-PROOFING - Smart contracts have started to be used to settle payments using cryptocurrencies automatically. Smart contracts remove the need for arbitration from a trusted party, thereby making the process much faster./p>

5. Create agile supply chains

Using AI and machine learning, SCM could build models to predict future events and be prepared for it. Currently, not many companies are leveraging this technology. However, the COVID-19 pandemic could be an eye-opener and motivate the supply-chain industry to become more agile in the coming year.

Another aspect of agility in the supply chain is the personalisation of shipments. As industries move towards giving more power to the end customers, easy customisations are both a necessary edge and an eventual need.

HAVE A FLEXIBLE, SCALABLE WMS - Companies need to build infrastructure that allows customisation of orders within the supply chain, and future adjustments, without adding to the cost of transactions or needing additional or new integrations.

6. Layered technologies

We discussed the various technologies that are being adopted by the supply-chain industry. However, it leads to a larger trend: the layering of multiple technologies. The supply-chain industry has understood that it can no longer treat technology as an isolated service, i.e., as a means to an end. Technology will inevitably become the backbone of the supply-chain industry.

CHOOSE COMPREHENSIVE SOLUTIONS, EASY INTEGRATIONS - Your software should have longevity, meaning it is both an experienced product while also one that constantly improves and looks towards the future. While it should have multiple excellent offerings, a WMS for example should be able to integrate easily with your ERP.

7. Potential Warehouse Labour Concerns

There is not yet an emerging technology that will significantly reduce the overall need for human workers, and fully automated warehouses are unlikely to show up for several years yet, although there are some major steps in that direction in China. Economics may push things in other directions, however.

Overall, Saudi Arabia is a robust employment and economic market with vast resources. A growing logistics industry must meet governmental pressures for increases in employment of Saudis, meaning local employers must rethink labour plans and adapt their systems and training accordingly.

Read our blog on typical workforce challenges in Saudi Arabia.

8. Ecommerce Will Accelerate

The pandemic has shifted the move to ecommerce, and if companies can fulfil this successfully, it is likely to continue even afterwards. This increase in demand will put pressure on warehouse technology. We've already seen shipping times grow at major ecommerce retailers, and the postal service burdened as smaller retailers try to pivot to online.

Meeting these higher levels of demand will result in more and more warehouses turning to full automation, including picking robots, not to replace human staff but to supplement.

ARE YOUR SYSTEMS ECOMMERCE READY? Choose technology to facilitate this expansion, ensure end-to-end processes for fast fulfilments, and ensure your customers are return customers.

The supply-chain industry stands amidst unprecedented times. However, the future holds great promise. By embracing innovation in the form of various technologies, the industry is all set to face the challenges in the times to come and help businesses achieve greater operational efficiency.

See where your warehouse stands with our handy benchmarking checklist:

TAGS

- WMS (51)

- Warehouse Best Practice (46)

- Implementing a WMS (29)

- Managing your warehouse (19)

- Omni Channel (18)

- eCommerce (18)

- Blog (16)

- Supply Chain Best Practice (16)

- Customer Journey (9)

- Mid-Level (8)

- Warehouse optimisation (7)

- General Tips (5)

- Industry General (5)

- Information (5)

- Trends (5)

- managing your Supply Chain (5)

- saudi arabia (5)

- Press Release (4)

- smart warehouse (4)

- 3PL (3)

- News (3)

- ERP (2)

- Entry-level (2)

- ROI (2)

- Case Study (1)

- OMS (1)

- Picking (1)

- Solution-Specific (1)

- Transport Management System (1)

Take A Look At The Results Of A Successful WMS Implementation.

See how Tarsus Distribution, in collaboration with SCJ boost overall efficiency by 60%