The Core Considerations of Integrating a WMS with your ERP

It’s time to implement a Warehouse Management System in your business. What now?

Your implementation is guided by your business’ functional requirements, reliant on and informed by the existing systems you use to manage your business processes.

Any WMS you choose to implement must be integrated with your host systems and designed to leverage these existing structures to improve your processes.

When implementing a WMS from an ERP vendor, there is typically an integration effort as most ERP WMS modules have either been purchased and integrated over time and as such are interfaced to the core ERP rather than being part of the standard package.

For a full list of ERP vs WMS pros and cons, read the blog: ERP vs. WMS – Which is the best fit for your business?

The answer, in short: whatever is fit-for-purpose, specific to your business.

We go through the options, and give pointers on establishing what you need, how it should be implemented, and what interface or integration needs to be incorporated into the design.

Integration vs Interface: What’s the Difference?

Integration refers to the full package, where several modules of a solution are already connected or built on the same platform and share data and updates between those modules based on specific actions and reactions.

Interfacing refers to the linking of systems through point-to-point data transfers and allows you to compile a set of tools that give you the right functionality for your business, while the scalability and performance of each component matches the exact requirement.

A WMS is specifically designed to optimize your warehouse operations. ERP software, on the other hand, is designed to automate processes across your entire business - from marketing and sales to human resources, client service, procurement, inventory and financial management.

Since an ERP is not traditionally integrated with a comprehensive warehouse management system, your warehouse will form only one of many minor modules within the business ecosystem.

To get a warehouse-focused, flexible, and functional warehouse management system, you will need to add modules to your ERP, custom-design a solution, or interface with a best-of-breed WMS that delivers all of your requirements in a single package.

The Business Considerations for WMS-ERP Integration:

What role will each system play in your business?

Check your actual requirements against the features of each system and work out where each one can support your day-to-day operations.

What are your long-term business goals?

Implementing systems that drive your business to achieve set goals and track to your KPIs is critical. See how each tool can satisfy these requirements and spec the implementation to ensure that all your objectives are met.

What ROI will your ERP/WMS integration deliver?

Will implementing a warehouse-focused WMS which interfaces with your existing ERP give you the most value

Fit-for-purpose: assessing your planned WMS/ERP integration

- Will it improve productivity within your warehouse?

- Will it drive profitability through better scheduling, management, and inventory control?

- Does it give you an end-to-end automation of your entire process?

- Does it improve the operational and functional depth of your current management system?

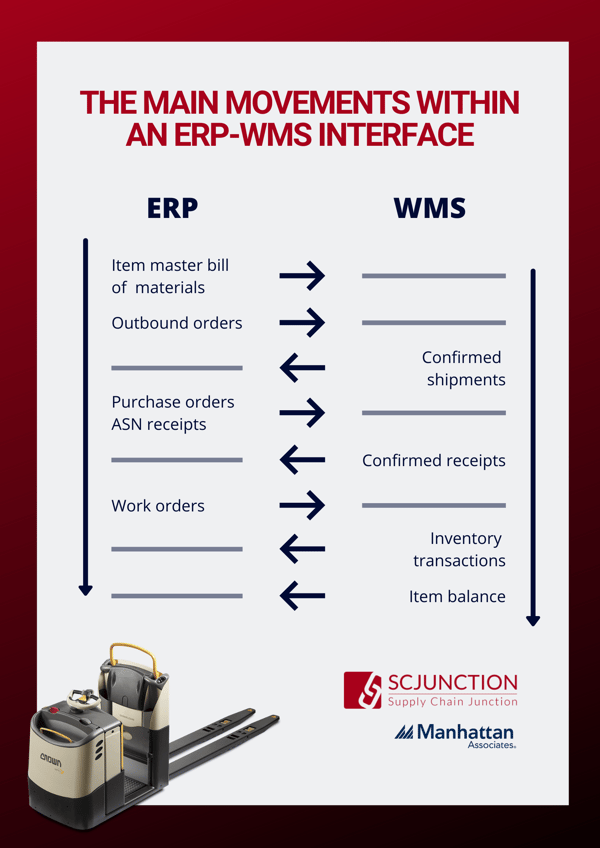

How does the interface of WMS to ERP work?

The desired outcome of an ERP and WMS integration is that your automated business processes and your Warehouse Management processes are working in tandem and assisting your sales, customer service, operations, and finance in making better, more strategic decisions.

There are three ways that this can be achieved:

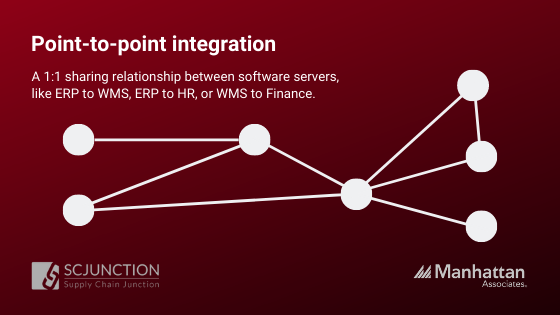

1. Point to Point Integration

This is the most direct way of integrating by sharing the required files from one system to another.

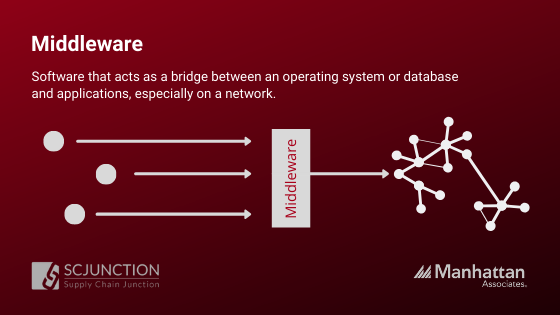

2. Via Middleware

When your business has multiple systems that need to interface, share data, and communicate in order for the business to function optimally, a Middleware solution is implemented as the centre of the system.

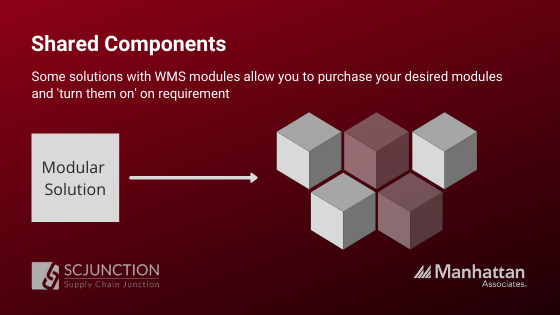

3. Shared Components

Some solutions are built in a modular way that allows you to “turn on” the required functionality if required. This method seldom requires extensive interfacing or integration.

In summary, your aim should be to determine the roles of each software, split out the functions and features, and use this data to give direction to your technical integration process. The outcome should be scalability, flexibility, and integration that manages any complexity of tasks.

See how a strategic implementation of your WMS can help you to optimise and improve your warehouse processes in order to help support your business objectives:

TAGS

- WMS (51)

- Warehouse Best Practice (46)

- Implementing a WMS (29)

- Managing your warehouse (19)

- Omni Channel (18)

- eCommerce (18)

- Blog (16)

- Supply Chain Best Practice (16)

- Customer Journey (9)

- Mid-Level (8)

- Warehouse optimisation (7)

- General Tips (5)

- Industry General (5)

- Information (5)

- Trends (5)

- managing your Supply Chain (5)

- saudi arabia (5)

- Press Release (4)

- smart warehouse (4)

- 3PL (3)

- News (3)

- ERP (2)

- Entry-level (2)

- ROI (2)

- Case Study (1)

- OMS (1)

- Picking (1)

- Solution-Specific (1)

- Transport Management System (1)

Take A Look At The Results Of A Successful WMS Implementation.

See how Tarsus Distribution, in collaboration with SCJ boost overall efficiency by 60%