The New Drivers Of Supply Chain Management Today

The capabilities of your supply chain are determined by the decisions you take in response to supply chain drivers, but equally each of these drivers can be developed and managed to emphasise effectiveness or efficiency, depending on changing business and economic requirements.

Understanding the drivers of Supply Chain Management and what they mean to your business starts with understanding your customers. Customer demands and expectations fuel supply chains globally - whether or not you're under pressure, your consumer base is the key to knowing where to drive, how to drive, and what to drive in your supply chain.

The 7 consumer drivers of supply chains

Consumer drivers centre on ultimate customer satisfaction. Response times, accuracy, delivery promptness, shipment specifications, tracking, and communication are key. These drivers translate into your capabilities within the supply chain, and can be summarised as:

Ensuring these protocols work efficiently, and are followed correctly, gives you a head start on competitors. From here, your next steps are to focus on the traditional drivers of supply chain management:

The 5 classical drivers of supply chains

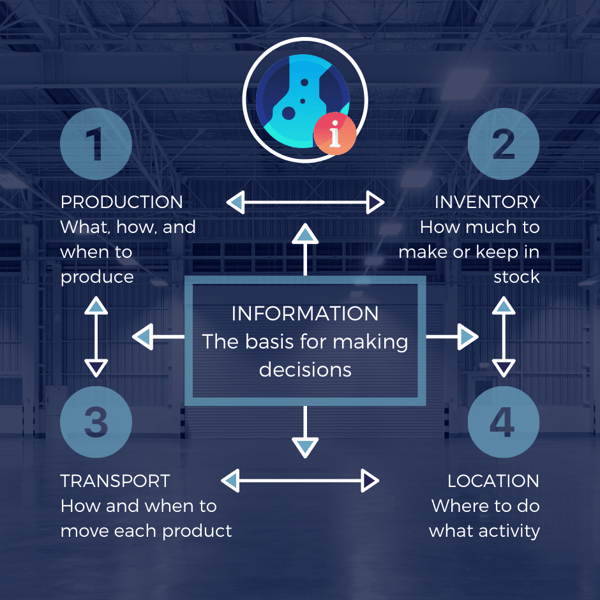

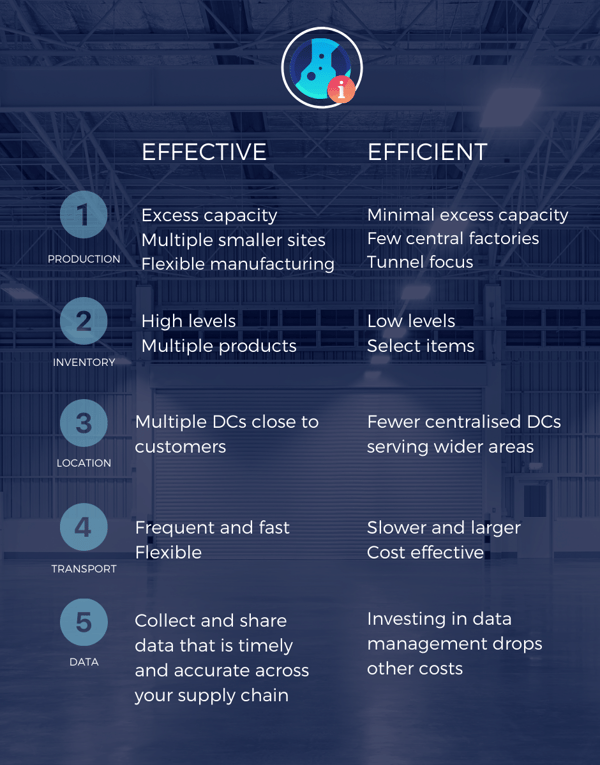

There are five classical drivers that provide a useful framework for adjusting your supply chain capabilities. Decisions made about how each driver operates will determine the blend of responsiveness and efficiency a supply chain is capable of achieving.

1. PRODUCTION

Keep production effective by ensuring factories that have maximum capacity and use flexible manufacturing techniques to produce a wide range of items. Alternatively companies can do their production in multiple, smaller plants, close to major distribution centres / customers so delivery times can be expedited.

If efficiency is desirable, then companies can build factories with minimal excess capacity, and optimise factories to produce a limited range of items. Gain further efficiency by concentrating production in large, central plants to get better economies of scale, accepting that delivery times might be slightly longer for production gains.

2. INVENTORY

Decisions about inventory are simulated by setting production rates and delivery schedules for products, and by defining on-hand amounts for different products at facilities throughout the supply chain.

Effectiveness can be ensured by stocking high levels of inventory for a wide range of products, as well as by stocking products at multiple locations - this means your inventory is both close to customers, and immediately available.

Conversely, efficiency in inventory management calls for reducing inventory levels of all items (particularly slower-moving or less popular items), while meeting economies of scale and cost savings by stocking inventory in only a few central locations, such as regional distribution centers (DCs).

3. LOCATION

A location decision that emphasises the effective would be one where a company establishes many locations that are close to its customer base. For example, fast-food chains use location to be very responsive to their customers by opening up lots of stores in high volume markets.

Efficiency can be achieved by operating from only a few locations and centralising activities in common locations, such as the way e-commerce retailers serve large geographical markets from only a few central locations that perform a wide range of activities.

Consider this decision by simulating your various facilities in selected locations, and then define the storage capacities and operating expenses for those facilities.

4. TRANSPORT

Effective transportation modes are fast and flexible, such as trucks and airplanes. Many companies that sell products through catalogs or on the Internet are able to provide high levels of responsiveness by using transportation to deliver their products often within 48 hours or less.

Efficiency can be met by moving products in larger batches, less often, with slower but bulk carriers such as ship or railroad. Transportation can also be made more efficient if it originates out of a centralised distribution center as opposed to multiple separate branches.

5. DATA

The power of information grows stronger every year as the technology for collecting and sharing information becomes more accessible, affordable, and easier to use. Data is like money - it is a valuable commodity because it can be applied directly to make decisions that enhance the performance of the other supply chain drivers.

For ultimate effectiveness, your supply chain should collect, collate, and share accurate and timely data generated by the operations of the previous four drivers. Consider the supply chains that serve the electronics market; they are some of the most responsive in the world. Companies in these supply chains, the manufacturers, distributors, and the big retailers all collect and share data about customer demand, production schedules, and inventory levels.

This enables these supply chains to respond quickly to situations like the Covid pandemic, and new market demands in the high-change and unpredictable economy we find ourselves in.

This summarises what can be done to guide the five supply chain drivers - companies and supply chains must continually adjust their balance of effectiveness vs efficiency as situations change to consider both customer satisfaction and costs.

Companies that make best use of information to increase their internal efficiency, and increase their responsiveness to external supply chain partners will gain the most customers and be the most profitable.

Embrace Technology

New technologies are making massive impacts on how supply chains operate. And yet after all is said and done, these new technologies can be employed to do one of two things: increase efficiency or increase responsiveness, hopefully some blend of the two.

GLOBALISATION OF SUPPLY CHAINS:

IS IT BACK-PEDALING?

Economists are predicting that Covid-19 will fundamentally reshape global trade, as companies look to reduce their dependence on globalisation and Chinese manufacturing in favour of local suppliers.

In a report published in May, the Economist Intelligence Unit (EIU) said the pandemic will not only halt but reverse globalisation by accelerating a move toward regional supply chains.

This shift away from China would be indicative of a wider trend, the report said, as global firms looked for ways to build up their resilience following the supply shock induced by the coronavirus.

“By building quasi-independent regional supply chains in the Americas and Europe, a global company will provide a hedge against future shocks to their network,” the EIU said. “For those companies that have this luxury already, they have been able to shift production of key components from one region to another as lockdowns and factory closures resulting from coronavirus have unfolded.”

Find out more about how you can bolster your supply chain with the right mix of technology in your Warehouse, and optimise your processes to ensure smooth delivery.

TAGS

- WMS (51)

- Warehouse Best Practice (46)

- Implementing a WMS (29)

- Managing your warehouse (19)

- Omni Channel (18)

- eCommerce (18)

- Blog (16)

- Supply Chain Best Practice (16)

- Customer Journey (9)

- Mid-Level (8)

- Warehouse optimisation (7)

- General Tips (5)

- Industry General (5)

- Information (5)

- Trends (5)

- managing your Supply Chain (5)

- saudi arabia (5)

- Press Release (4)

- smart warehouse (4)

- 3PL (3)

- News (3)

- ERP (2)

- Entry-level (2)

- ROI (2)

- Case Study (1)

- OMS (1)

- Picking (1)

- Solution-Specific (1)

- Transport Management System (1)

Take A Look At The Results Of A Successful WMS Implementation.

See how Tarsus Distribution, in collaboration with SCJ boost overall efficiency by 60%