Why local warehouses should benchmark against global best practices

.png)

.png?width=900&height=375&name=Untitled%20design%20(99).png)

With globalisation turning the world into a “global village”, local businesses need to start benchmarking against global best practices if they want to maintain their competitive edge in the market.

Who are your biggest competitors? Take a moment to list them.

If your mind leapt straight to other national brands, chances are you’re mistaken. Your biggest competitors may not be found locally, in fact, they may not even be in your industry.

When it comes to customer service, your customers aren’t comparing you to other national brands. They’re comparing you to every digital interaction they’ve ever had. That’s some tough competition. Whether you know it or not, your competitors are brands like Amazon, Walmart, Ikea and Bed, Bath & Beyond.

This is thanks to globalisation.

How does globalisation affect supply chain management?

Unless you’ve spent the past two decades or so living under a rock, you’ve likely encountered the terms "globalisation” and “global village” with increasing frequency.

For those who’ve never encountered these two terms, here’s a quick definition. . . According to the Oxford English Dictionary, globalisation is “the process by which businesses or other organisations develop international influence or start operating on an international scale”. Global village is defined as “the world considered as a single community linked by telecommunications”.

The term “global village” was coined by the Canadian philosopher, Marshall McLuhan, in the 1960’s, to describe the convergence of space and time through advanced technology.

Globalisation is both a blessing and a curse. On one hand, it opened up a new world of opportunities for brands (in the form of new customers and markets), on the other hand, globalisation brought with it a new set of risks. You’re no longer looking to your backyard for competition - you’re competing with world leaders.

The traditional supply chain model isn’t equipped to handle the demands of a globalised supply chain. TechWire Asia writes, “Customers expect more, products are updated and introduced faster than ever, new companies enter the market daily — there are so many things to keep up with that a lack of agility and scalability can cost an organization dearly.”

Globalisation makes supply chain management both increasingly complex and critical to your bottom line.

According to TechWire Asia, “Supply chain innovators have 60 percent better profit margins and 65 percent better earnings per share than their competitors and the impact [of effective supply chain management] becomes clear. These supply chain innovators have identified the shortcomings of their rigid, legacy applications, and have moved toward building a modern, flexible, end-to-end supply chain that’s more suited to the dynamic challenges of today’s business world.”

But how do you achieve a world class supply chain? It starts with research, planning and benchmarking your warehouse processes - not against other South African brands necessarily, but against brands whose success you’d like to emulate.

Benchmarking against global best practices

Benchmarking your warehouse processes against world leaders (also known as qualitative benchmarking) will future-proof your business.

Benchmarking will not only give you a clear indication of where your warehouse stands currently, in comparison to competitors, but it will lay the foundations for ongoing optimisation, testing and measurement.

There are several key benefits derived from benchmarking:

- You’ll identify industry best practices which can be applied in your supply chain

- You’ll be able to establish realistic goals and time frames

- You’ll establish accurate measurements of productivity and ROI

- You’ll gain valuable insight on your competitors’ operations

- You’ll improve your ability to meet the needs of your customers

Need help benchmarking your warehouse operations? Our supply chain experts will assess your needs and make recommendations to help you achieve world class industry best practices.

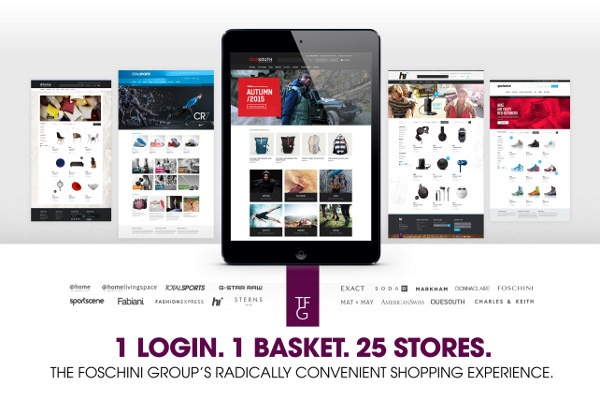

Take a look at how the South African retail company, The Foschini Group, updated their supply chain to deliver a world class customer experience.

What does a world class supply chain look like locally?

Image source: The Foschini Group

The Foschini Group (TFG) is a great example of a world class supply chain in action. Using the Manhattan WMS, TFG managed to to reduce logistics lead times from 17 to 4.9 days in their distribution centres (DCs). They managed to achieve additional excellent results including:

- A DC stock holding reduction of 64%

- An overall delivery conformance improvement of 11.5%

- DC pick accuracy consistently at 99.9%

What are you waiting for? Take the next step towards business excellence and get your free benchmarking assessment. Our supply chain experts will assess your needs and make recommendations to help you achieve industry best practices.

TAGS

- WMS (51)

- Warehouse Best Practice (46)

- Implementing a WMS (29)

- Managing your warehouse (19)

- Omni Channel (18)

- eCommerce (18)

- Blog (16)

- Supply Chain Best Practice (16)

- Customer Journey (9)

- Mid-Level (8)

- Warehouse optimisation (7)

- General Tips (5)

- Industry General (5)

- Information (5)

- Trends (5)

- managing your Supply Chain (5)

- saudi arabia (5)

- Press Release (4)

- smart warehouse (4)

- 3PL (3)

- News (3)

- ERP (2)

- Entry-level (2)

- ROI (2)

- Case Study (1)

- OMS (1)

- Picking (1)

- Solution-Specific (1)

- Transport Management System (1)

Take A Look At The Results Of A Successful WMS Implementation.

See how Tarsus Distribution, in collaboration with SCJ boost overall efficiency by 60%

.png?width=65&height=65&name=Untitled%20design%20(39).png)