What should you expect from your WMS supplier?

.png?width=900&name=Untitled%20design%20(7).png)

What happens after the initial WMS implementation? We’re demystifying the long-term relationship and responsibilities between WMS supplier and client, to show you how you can get the most out of your partnership.

You’ll often hear us mention that your WMS provider will be your partner for the next 10 to 15 years (so pick wisely). We want to help you understand the value in viewing your WMS provider as your go-to source of information to help you optimise your supply chain - not just maintaining your software.

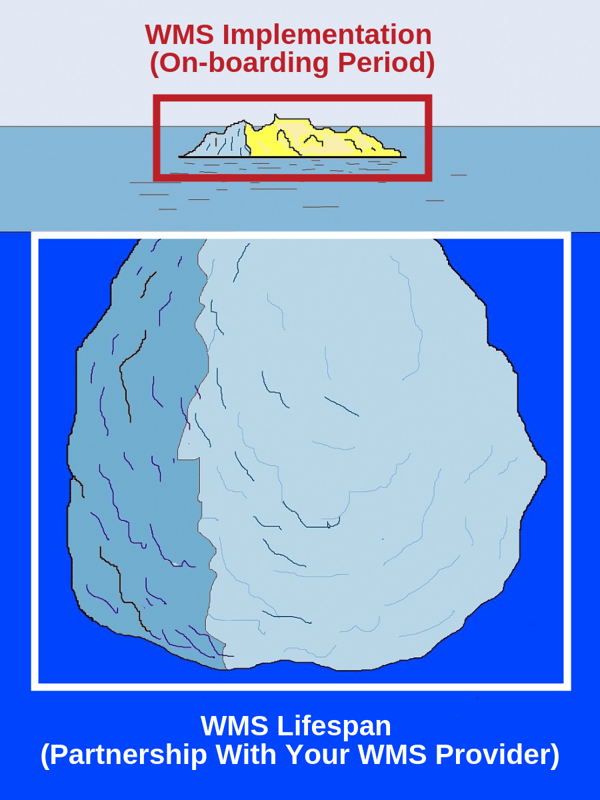

Imagine the lifespan of your WMS as an iceberg

Implementing a WMS (the first six to 12 months) is only the tip of the iceberg. The remaining 14 plus years of your relationship with your WMS provider sit beneath the water - but what happens during this time?

Often, we find that customers aren’t sure what to expect from their WMS supplier beyond the initial WMS implementation. They’ll only contact their WMS provider when there’s a problem with the system and they need technical support.

From a service level perspective, your WMS supplier is indeed required to offer you technical support - fixing any glitches with the system.

However, this is a very superficial view of the value your WMS supplier can offer. Yes, you can buy a “box-drop” solution - where your WMS provider drops off their software and leaves you to fend for yourself, but is this the type of relationship you really want? Probably not.

People, process and technology: the pillars of a successful WMS implementation

The idea of people, process and technology (or “the golden triangle”) was first coined by the American cryptographer, Bruce Schneier, in the 1990’s. The golden triangle suggests that a balance between these three areas must be struck, to enjoy the maximum benefits of a new technology.

The physical implementation of a WMS (or any new technology) is usually successful. In fact, most unsuccessful implementations are not due to the software itself - but rather to the warehouse processes and people operating the system.

When there’s a misalignment between your WMS and your warehouse layout or processes, you won’t see the results you hoped for. The same applies to your team. If they haven’t been given sufficient training on the new software, and the change was managed poorly, your staff won’t be able to leverage the full capabilities of your WMS.

So, how do you overcome these challenges to achieve the golden triangle? Your WMS provider of course!

The benefits of a professional services retainer (PSR)

There are two main benefits to having a PSR with your WMS provider.

Strategic advice to help you manage change

What you really want, is a WMS provider who shows you where you need to optimise to extract maximum benefit from the system and improve your ROI. If you’ve partnered with the right WMS provider, they’ll be able to offer you all the expert guidance you need to ensure that both the people and processes in your warehouse support your new system.

With over 20 years of experience optimising the supply chains of various different industries, we’re able to help you:

- Identify which technology and best practices will best suit your business needs

- Implement processes to improve inventory control and predict patterns of demand

- Predict potential challenges and disruptions to minimise their impact on your business

- Optimise your warehouse layout

- Provide training to ensure your team get the most out of your WMS

- Reduce your day-to-day operating costs

Access to the latest WMS technology on the market

Software has a defined life cycle - usually no more than five years. Your WMS will need to be updated as features are upgraded and new ones are added. Your WMS provider needs to keep you fully informed on these new features, to help future-proof your business.

Tips when partnering with a WMS provider

If you truly want to get the most out of your partnership with your WMS provider, then lean on them as much as you can. Our job is to be the warehouse experts, while your job is to be the expert in your industry - whatever that may be.

- A make a commitment to continuous improvement

- Allocate enough budget for future system upgrades

- Choose a WMS partner who has your best interest at heart

- Be willing to embrace change and learn new technologies

- Share your business strategy to ensure both parties are on the same page

- Alert your WMS supplier if you identify a weak point in your warehouse or an area that isn’t performing as well as you would like

- Accept your WMS provider as an expert partner and strategic advisor

The more openly you communicate with your supplier, the easier it is for them to step in and help you streamline your supply chain.

From benchmarking your warehouse, to labour optimisation and managing returns, we’ll help you run a lean operation. Download our Practical Guide to Optimising Your Warehouse

.Stay up to date with the latest trends in the supply chain industry.Subscribe to Supply Chain Matters, and we’ll send all of our latest helpful tips and tools, straight to your inbox.

TAGS

- WMS (51)

- Warehouse Best Practice (46)

- Implementing a WMS (29)

- Managing your warehouse (19)

- Omni Channel (18)

- eCommerce (18)

- Blog (16)

- Supply Chain Best Practice (16)

- Customer Journey (9)

- Mid-Level (8)

- Warehouse optimisation (7)

- General Tips (5)

- Industry General (5)

- Information (5)

- Trends (5)

- managing your Supply Chain (5)

- saudi arabia (5)

- Press Release (4)

- smart warehouse (4)

- 3PL (3)

- News (3)

- ERP (2)

- Entry-level (2)

- ROI (2)

- Case Study (1)

- OMS (1)

- Picking (1)

- Solution-Specific (1)

- Transport Management System (1)

Take A Look At The Results Of A Successful WMS Implementation.

See how Tarsus Distribution, in collaboration with SCJ boost overall efficiency by 60%