Warehouse Automation: what is the difference between a WMS, WES, and WCS?

Warehouse management may seem like a straightforward business when looking at it from a distance. Digging a bit deeper, it becomes more complicated. Especially when integrating your warehouse management system (WMS) with advanced material handling equipment (MHE) like automated conveyors, sorters, putwalls, and pick-to-light solutions.

Understanding the role of the different supporting warehouse systems can be quite a puzzle. Whether you are new to the field, have been managing warehouses for many years, or someone just looking to learn more about warehouse automation, getting a grip on this terminology will be helpful. To help clear up the confusion, this article will provide an overview of the differences between WMS, WES, and WCS.

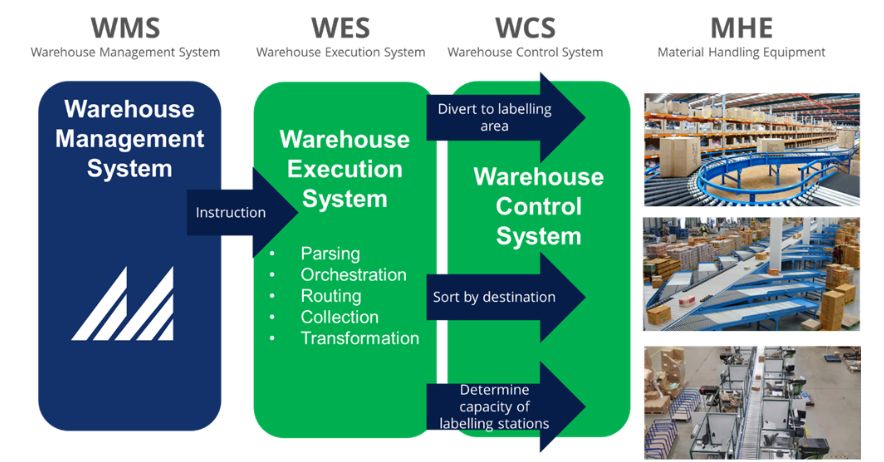

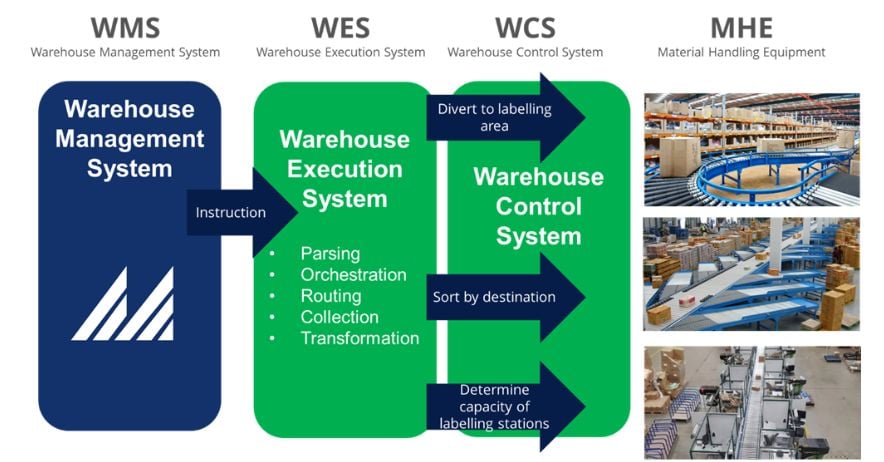

Warehouse Management System (WMS), Warehouse Execution System (WES), and Warehouse Control System (WCS) are the three core components of automated warehousing operations. Each of these systems has its own unique set of functions and capabilities, and they all work together to maximize efficiency and productivity in warehouses and distribution centres.

The Warehouse Management System (WMS) is the main system that manages key warehouse processes like receiving, replenishment, picking, and shipping. WMS is responsible for managing the allocations and instructions to move goods in the warehouse, ensuring that all orders are fulfilled correctly, and that system stock levels reflect the physical stock levels.

The Warehouse Execution System (WES) is a system used to control the physical movement of materials and goods in the warehouse. WES receives instructions from WMS as inventory is being processed. For example, this information could contain instructions to divert a carton to a labelling station, to sort cartons by destination, or to determine capacity of pack stations. All these different instructions must be executed by material handling equipment. The WES ensures that the right instructions, flow to the right piece of material handling equipment. Messages from WMS are parsed, orchestrated, and routed by the WES and may even be formatted and transformed to accommodate the WCS.

The warehouse control system (WCS) is the piece of software that controls the physical behaviour of MHE. Multiple warehouse control systems can be plugged into one WES, it is therefore essential that the instructions from WES are in the format and mapping that the WCS understands. If the initial WMS instruction is not accurate, the physical movement of the inventory may also be incorrect. Cartons could end up at the wrong destination, conveyers could clog up and inventory could even be damaged.

Get in touch to learn more about Manhattan’s WMS and WES solutions.

TAGS

- WMS (51)

- Warehouse Best Practice (46)

- Implementing a WMS (29)

- Managing your warehouse (19)

- Omni Channel (18)

- eCommerce (18)

- Blog (16)

- Supply Chain Best Practice (16)

- Customer Journey (9)

- Mid-Level (8)

- Warehouse optimisation (7)

- General Tips (5)

- Industry General (5)

- Information (5)

- Trends (5)

- managing your Supply Chain (5)

- saudi arabia (5)

- Press Release (4)

- smart warehouse (4)

- 3PL (3)

- News (3)

- ERP (2)

- Entry-level (2)

- ROI (2)

- Case Study (1)

- OMS (1)

- Picking (1)

- Solution-Specific (1)

- Transport Management System (1)

Take A Look At The Results Of A Successful WMS Implementation.

See how Tarsus Distribution, in collaboration with SCJ boost overall efficiency by 60%