Why Choose SCJ and Manhattan? Your Implementation Success

Ultimately, the proof of any system is in the outcome. Supply Chain Junction and Manhattan Associates know how superior our offerings are, but you don't need to take our word for it: speak to the clients who have experienced the same process and seen the outcomes.

Whether your warehousing needs are purely 3PL or need the holistic resources of retail. wholesale, pharmaceutical and omnichannel, you need the best WMS to capitalise on your warehouse operations. The Manhattan warehouse management system is for you.

How we assess your business

Our experience allows us to assess your supply chain and identify how it can be adapted to function optimally. This is done in a data-driven and strategic manner:

.png?width=900&name=Case%20Studies%20Benefits%20Intro%20Manh%20%26%20SCJ%20(2).png)

Supply Chain Junction & Manhattan as a partner: The benefits

- Multi-region capability: Whether in the Middle East or South Africa, our team will be present throughout the entire life-cycle of your project and, if you choose, the warehouse design process

- Leading WMS in your vertical: Nearly 50% of all WMS transactions in the retail apparel, and 20% in both Grocery, Food and Beverage, 3PL, Pharmaceutical and Wholesale verticals are made with Manhattan.

- A thriving customer community: We have engaged customer community in both South Africa and the rest of the world. Tap in and share your experiences!

- Innovation and Investment: Almost US$80 million was spent on R&D last year, with innovations such as order streaming, in-built WES, embedded labour and slotting within the WMS and mobile apps.

Retail Case Study

Foschini Group Reduces Logistics Cost by 10%

Supply Chain Junction assisted the transformation of their supply chain and continues to do so in an ongoing process, building success upon success.

CHALLENGE

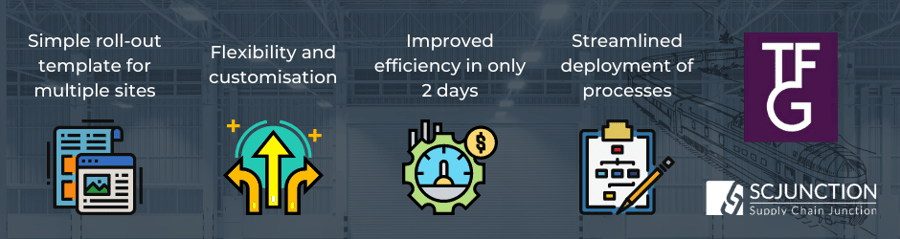

The legacy system was struggling to cope with the sharp peaks in customer demand and the need to adapt to change in a short space of time. They needed much more flexibility and a template for quick, effective roll-out across divisions.

PROCESS

Manhattan's retail and domain expertise made it an obvious choice, not only highly ranked by independent analysts but by positive results. The first site implementation was complete within 12 months but created a template for other sites; the second site was live after just two months. The WMS was delivered on time and under budget, and within two days of going live was shipping in excess of their store distribution plan.

RESULT

"We have met one of our main objectives in that we have designed a series of system templates which can be dropped into the remaining sites. Whereas it may previously have taken us up to six months to deploy cross-docking with our legacy system, we can now do the same thing in a matter of days,” explained Jan Tukker.

3PL CASE STUDY:

Global Shipping & Logistics Accelerates Middle East Expansion

.png?width=900&name=GSL%20Benefits%20(1).png)

In their quest to becoming the leading 3PL provider in the UAE, GSL evaluated several solutions - they felt strongly that the partner companies that form a supply chain should be able to exchange critical supply chain data at any time.

CHALLENGE

GSL wanted to deploy the most advanced supply chain solutions available on the market in order to become the number one warehousing service in the Middle East in both size and inventory handling services.

PROCESS

Manhattan Associates solution provided flexibility, full visibility and integrated billing management upon implementation; they continue to be able to scale up with the change in business and solution demands.

RESULT

The results have exceeded expectations:

Products for 40+ blue-chip clients filled two new warehouses within seven months of going live; clients place and track orders online; inventory accuracy averages 99.8%; IT manpower requirements are minimal; people can be trained on the system very easily. Business has been so successful that GSL commissioned phases two and three of the project, building out five more warehouses within 18 months.

Download the full GSL case study here:

There are numerous other clients with whom we've achieved great success, including DHL, Bolloré, and Cotton On.

Get more details from us by booking a meeting to discuss your WMS requirements and our track record:

Or find more case studies here:

TAGS

- WMS (51)

- Warehouse Best Practice (46)

- Implementing a WMS (29)

- Managing your warehouse (19)

- Omni Channel (18)

- eCommerce (18)

- Blog (16)

- Supply Chain Best Practice (16)

- Customer Journey (9)

- Mid-Level (8)

- Warehouse optimisation (7)

- General Tips (5)

- Industry General (5)

- Information (5)

- Trends (5)

- managing your Supply Chain (5)

- saudi arabia (5)

- Press Release (4)

- smart warehouse (4)

- 3PL (3)

- News (3)

- ERP (2)

- Entry-level (2)

- ROI (2)

- Case Study (1)

- OMS (1)

- Picking (1)

- Solution-Specific (1)

- Transport Management System (1)

Take A Look At The Results Of A Successful WMS Implementation.

See how Tarsus Distribution, in collaboration with SCJ boost overall efficiency by 60%