The Future, Now: 8 Ways Machine Learning Transforms Warehousing

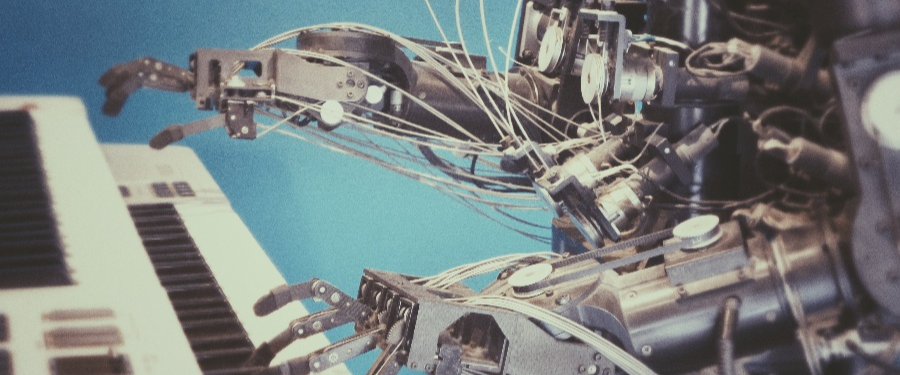

"Artificial Intelligence" and "Machine Learning" have recently become buzzwords across different verticals, but what do they actually mean for modern supply chain management?

A smart warehouse combines various interconnected technologies to form an ecosystem whereby an entire business operation, from supply to delivery, is governed by AI. Goods are received at the warehouse, identified and sorted, processed, packaged, and pulled for shipment, all automatically and with minimal margin for error.

Warehouse management will become more agile, with faster responses to logistical demands of material items and personnel, and more scalable in terms of finding new solutions for greater volume and flow of product.

Machine Learning and Warehouse Management

Integrating machine learning in supply chain management can help automate a number of mundane tasks and allow the enterprises to focus on more strategic and impactful business activities.

It could assist enterprises to create an entire machine intelligence-powered supply chain model to mitigate risks, improve insights, and enhance performance, all of which are critical to build a competitive and sustainable supply chain model with future longevity.

A recent study by Gartner also suggests that innovative technologies like Artificial Intelligence (AI) and Machine Learning (ML) would disrupt existing supply chain operating models significantly in the future - if the global pandemic should teach us anything, it is that we should not resist future evolution to platforms, such as businesses that resisted the transformation to eCommerce and omnichannel chains.

Considered as one of the high-benefit technologies, ML techniques enable efficient processes resulting in cost savings and increased profits.

Using intelligent machine learning software, supply chain managers can optimise inventory and find most suited suppliers to keep their business running efficiently.

An increasing number of businesses today are showing interest in the applications of machine learning, from its varied advantages to fully leveraging the huge amounts of data collected by warehousing, transportation systems, and industrial logistics.

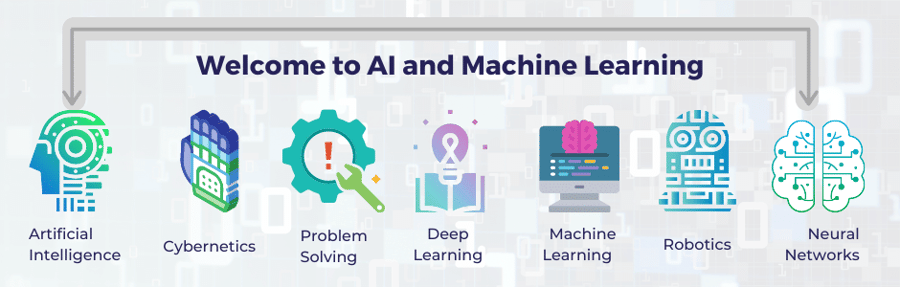

The business challenges that machine learning and AI can solve:

Fully automated warehousing has not yet been achieved, but these are some of the ways AI will transform warehouse management:

How AI & machine learning will transform your warehouse management:

1. Productivity

Improve the productivity in pick-and-pack processes.

With ML enabling managers to leverage the efficiency of the most productive pickers so as to develop a fully integrated system-directed solution, processes are transformed and streamlined. Slotting software products already provides an interface that includes operating rules to be implemented in the smart warehouse, offering a recommended SKU strategy based on sales histories and forecasts. While actual people still use personal knowledge and experience to adjust the slotting strategy, this will be increasingly phased out in favour of ML algorithms.

2. Communication

Automated systems using AI and machine learning algorithms can communicate at an exponentially greater rate than human operatives.

Many warehouse-related activities are already automated, but introducing IoT-enabled devices into these processes will vastly improve both speed and accuracy. Wireless cloud data communications mean that all elements of your system can engage, with a dialogue that incorporates system monitoring and control. Additionally, deep learning processes enable the machines to conduct constant analysis of the data streams produced by these components, enabling them to implement real-time adjustments and improvements in an integrated WMS.

3. Wages

See a reduction of payroll expenses, initially be offset by the required technological investment.

Perhaps the most controversial way in which AI will transform warehouse management is in labour expenses. At the current stage of development, robot assistance impacts existing operations only as an aid to productivity, but AI could – and will – continue to improve machine handling capabilities, with 30% of UK warehousing jobs becoming fully automated by 2030. Likeliest sectors for automation are data collection, data processing, and predictable physical activities. Established eCommerce enterprises suggest that increasing their automation will create jobs by expanding the overall scale of their business activities, but this will be determined as it evolves.

4. Warehouse logistics

Operator error and processing times can be reduced, with corresponding increases in overall efficiency and productivity.

Another way AI will transform warehouse management is by optimising the logistics - consider calculating the number of pallets that need to be moved on any given day, how much equipment is required to handle that movement, and the corresponding labour requirement. Such calculations previously relied on variables such as operator skill level and SKU (stock keeping units), but now ML algorithms enable detailed stock movement forecasting and management to fine-tune material handling.

5. Inventory

Free up resources previously spent on inventory control for other business growth opportunities.

Radio frequency identification (RFID) is replacing paper trails and bar code scanners for the organisation and control of inventory, tracking products with digital tags and enabling a more precise and accurate inventory control. Because the system uses radio waves to transfer data around, RFID scanners don't need direct line-of-sight control, but are just pointed in the general direction of a product to identify it and direct its movement into, out of, and around the warehouse.

This aspect of the smart warehouse can also be linked to the central AI processing unit, adjusting the speed and volume of order processing to increase overall productivity. Forecasting demand for new products including the causal factors that most drive new sales is an area machine learning is being applied to today with strong results,proving to be valuable at taking into account causal factors that influence demand yet had not been known of before.

6. Robots

Robots can pick up goods and redistribute them within a fraction of the time required by human operatives.

ML algorithms can help warehousing bots select the most efficient picking and slotting routes and determine the best type of packaging based on the size, number, weight and type of product. Some machines now can even pack the products themselves, using AI to optimise the space and materials.

7. Visibility

Combining machine learning with advanced analytics, IoT sensors, and real-time monitoring is providing end-to-end visibility across many supply chains for the first time.

What’s needed in many supply chains today is an entirely new operating platform or architecture predicated on real-time data, enriched with patterns and insights not visible with previous analytics tools in the past. Machine learning is an essential element in future supply chain platforms that will revolutionise every aspect of supply chain management.

8. Data

Gaining greater contextual intelligence using machine learning combined with related technologies across supply chain operations translates into lower inventory and operations costs and quicker response times to customers.

Machine learning is gaining adoption in Logistics Control Tower operations to provide new insights into how every aspect of supply chain management, collaboration, logistics and warehouse management can be improved. Machine learning excels at visual pattern recognition, opening up many potential applications in physical inspection and maintenance of physical assets across an entire supply chain network.

Companies can also extend the life of key supply chain assets including machinery, engines, transportation and warehouse equipment by finding new patterns in usage data collected via IoT sensors.

AI and Machine learning make it possible to discover patterns in supply chain data by producing and interpreting algorithms that quickly pinpoint the most influential factors to a supply networks’ success, while constantly learning in the process. This habit of discovering new patterns in supply chain data has the potential to revolutionise any business.

Machine learning algorithms are finding these new patterns in supply chain data daily, without the need for manual intervention to guide the analysis; the algorithms iteratively query data with many using constraint-based modeling to find the core set of factors with the greatest predictive accuracy.

For the first time, key factors influencing inventory levels, supplier quality, demand forecasting, procure-to-pay, order-to-cash, production planning, transportation management and more are becoming known, giving us new knowledge and insights that are transforming supply chain management as we know it.

Get ready to automate: Check how your warehouse performs compared to industry standards, and prepare effectively for the digital warehouse transformation

TAGS

- WMS (51)

- Warehouse Best Practice (46)

- Implementing a WMS (29)

- Managing your warehouse (19)

- Omni Channel (18)

- eCommerce (18)

- Blog (16)

- Supply Chain Best Practice (16)

- Customer Journey (9)

- Mid-Level (8)

- Warehouse optimisation (7)

- General Tips (5)

- Industry General (5)

- Information (5)

- Trends (5)

- managing your Supply Chain (5)

- saudi arabia (5)

- Press Release (4)

- smart warehouse (4)

- 3PL (3)

- News (3)

- ERP (2)

- Entry-level (2)

- ROI (2)

- Case Study (1)

- OMS (1)

- Picking (1)

- Solution-Specific (1)

- Transport Management System (1)

Take A Look At The Results Of A Successful WMS Implementation.

See how Tarsus Distribution, in collaboration with SCJ boost overall efficiency by 60%