5 Ways to Deal with Customer Demand Distortions: The Bullwhip Effect

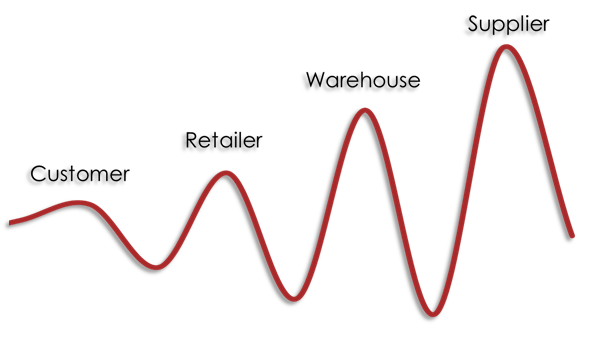

The customer is king, but it can be hard to predict what the king will need from your business. The customer demand distortion that travels along the supply chain is defined as bullwhip effect (also known as the Forrester effect). Imagine the customer holding a giant whip and giving it a bash, the ripples of the whip increase further down the line (i.e., supply chain). This illustrates the effect of customer demand distortions on the entire supply chain, all the way from the customer to the origin of the item.

Understand the impact of the bullwhip effect

Dealing with the bullwhip effect starts with understanding the definition and accepting the existence. Distribution centres across the world experience demand fluctuations. The bullwhip effect plays out slightly different across industries but the goal to prevent inventory shortages is one that applies to all of them. Before going into resolutions, it is key to understand what factors can contribute to demand fluctuations:

- Distribution Order Lead Times

- Order Batching

- Lack of Communication in the Supply Chain

- Inaccurate Forecasting

An example

Based on the forecast, the customer demand is 10 units. The retailer orders 20 units from the warehouse, just to be safe. The warehouse keeps 30 units in case the store demand unexpectedly peaks. To make sure the manufacturer can supply enough stock, even when the demand fluctuates, 40 units are manufactured.

At the end of the month, it turns out only 5 units have been ordered by our customers, while 40 have been produced!

5 ways to deal with the bullwhip effect

1. Improve Inventory Planning.

Reliable and thorough inventory planning starts with solid communication between the different players in the supply chain. Warehouse Management solutions can help with inventory synchronization between your WMS and systems used by other supply chain partners.

2. Review safety stock levels.

A common way to pro-actively mitigate the risk of having insufficient stock is to keep safety stock. As time progresses, customer demand changes and safety stock levels could be evaluated and adjusted down. Regular cycle counting with a WMS provides inventory accuracy and all the data required to do this exercise.

3. Evaluate order batching.

Orders can be batched into more manageable pieces before the demand reaches the WMS. When the customer demand changes, batches could result in excessive order quantities down the supply chain. OMNI-channel solutions and supply chain intelligence can help to streamline order inflow and optimize order batching.

4. Stabilize price fluctuations.

Recent trends show that the price of an item remains the main driver in customer behaviour. Stabilizing the price of an item can therefore stabilize customer demand. This method can have an impact at the very beginning of the bullwhip but is due to various financial considerations not always an option.

5. Improve forecast accuracy.

An accurate forecast helps to minimize customer demand distortions and contributes to keeping less safety stock. Forecast accuracy improvements depend on two major factors: choosing the right forecast technique that fits your business and accurate historical customer order data.

Want to know more? Get in touch and learn more about our best-in-class supply chain solutions.

TAGS

- WMS (51)

- Warehouse Best Practice (46)

- Implementing a WMS (29)

- Managing your warehouse (19)

- Omni Channel (18)

- eCommerce (18)

- Blog (16)

- Supply Chain Best Practice (16)

- Customer Journey (9)

- Mid-Level (8)

- Warehouse optimisation (7)

- General Tips (5)

- Industry General (5)

- Information (5)

- Trends (5)

- managing your Supply Chain (5)

- saudi arabia (5)

- Press Release (4)

- smart warehouse (4)

- 3PL (3)

- News (3)

- ERP (2)

- Entry-level (2)

- ROI (2)

- Case Study (1)

- OMS (1)

- Picking (1)

- Solution-Specific (1)

- Transport Management System (1)

Take A Look At The Results Of A Successful WMS Implementation.

See how Tarsus Distribution, in collaboration with SCJ boost overall efficiency by 60%