Implementing a Warehouse Management System

What is required to Successfully Implement a Warehouse Management System?

WMS Implementation

Once you’ve decided you need a WMS and chosen the right partner to help you implement your WMS, the next step is to plan, resource, and execute your implementation.

This page discusses the most important foundational elements and lessons learnt over the past 20 years. We’ve seen these as essential to ensuring a highly successful WMS outcome.

Ensure the WMS supports Corporate Strategy

Warehouse management systems are mission-critical technologies. They should be selected on the basis that they’re evolving strategic tools and supporting the organisation's long-term strategy and goals. Additionally, they need to be dynamic and able to adjust to changing market conditions, rather than tactical point solutions that only fix short-term problems. You can achieve this by considering the best in class technologies and benchmarking them against rival offerings.

Your chosen technology needs to be adaptable and meet different scenarios that may present themselves. Your WMS needs to evolve constantly, so it can meet changing industry-specific requirements and it needs to be scalable to facilitate future business growth. This is vital to support the company's long-term business direction and objectives.

A clear business case that documents the expected benefits at a business, process and financial level. This should be used to define critical success factors (CSFs) for the project and then tie into the post-project completion benefit realisation and ROI phase of the project.

In order to properly ascertain whether the implementation has been successful, key measures and a success criteria should be defined up front. They can be modified throughout the project, but they should always remain front and center, and ultimately drive future benchmarking and optimisation efforts.

What is the expected duration of a WMS project?

Implementation planning should take into account the time until the solution is fully implemented as well as the long-term timescale. On average it’ll take 6-8 months to fully implement a WMS. A further 1-3 month is needed for the bedding down process and then anywhere from another 3-12 months for full optimisation to be recognised. Organisations need to be prepared and aware of the entire process period.

Trust in the vendor/implementation partner

Whilst we have discussed the core elements for selecting a WMS partner here, once you have chosen a partner, they should immediately begin proving their worth by helping you plan the project and process effectively. They should also demonstrate their domain and product knowledge so as to provide you with the required level of comfort that you are going to have a successful outcome.

Your WMS partner and the team members that work on your project should form an integral part of the process, and whilst they will consist of around 50% of the team and task list on the project, their impact will account for around 80% of your success. As such, you need to build a trust relationship with them and follow their advice on best practice, common onboarding mistakes, timelines and project risks.

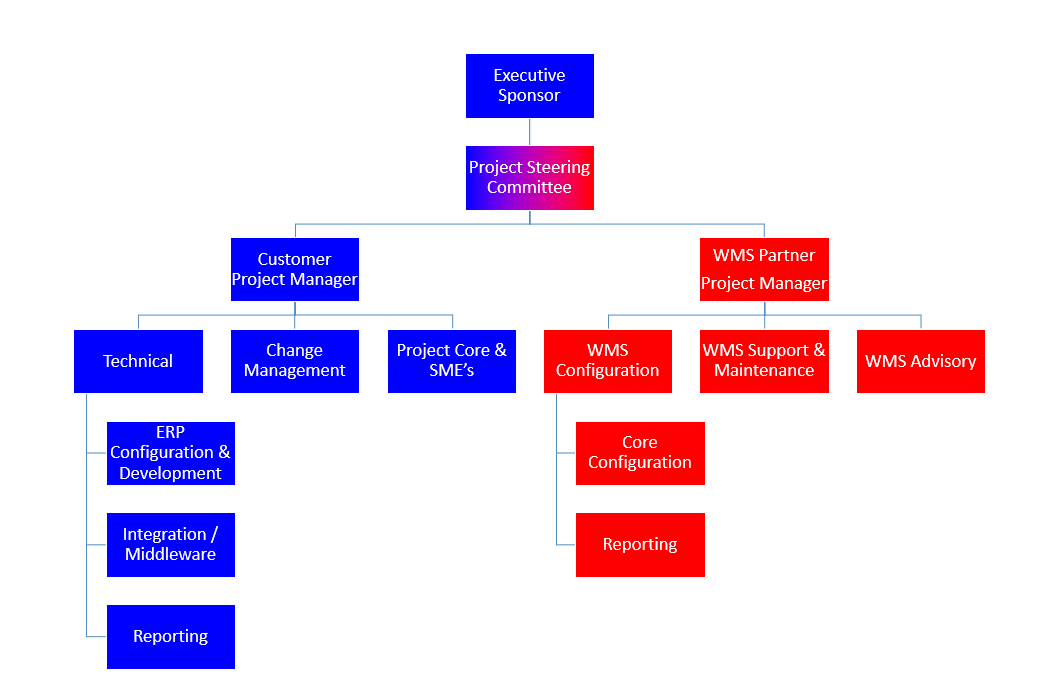

The right team and the right plan will make all the difference

Implementing a WMS is a complex, mission-critical process and requires the right blend of team members to ensure success. Below is an overview of the typical organisational structure of a WMS implementation project.

Project Management and Change Management are Critical to Success

If your company doesn’t already have experienced project and change management resources on staff, it should consider outsourcing this function to an experienced industry expert. We recommend seeking project and change managers with a least five WMS implementation projects under their belt.

Effective organisational change management, to prepare for the implementation, includes coordinating and communicating with various teams with different objectives. This is a complex but necessary part of project and change management. While some organisations have highly qualified project and change managers, many are stretched with existing projects. A project's success will hinge on the organisation's ability to make decisions, resolve issues, coordinate the activities of multiple departments and initiatives, and build the culture to support this.

Involve the operational team

Although software and technology is a major investment for any company, it's common to find highly effective and engaged IT teams. However, you shouldn’t limit representation from your operational team. Your IT team will ensure the technology performs as it should, but your operational team will receive the largest benefit and ROI from your WMS, and should be heavily involved in the process. Your operational team will ultimately be the end users of the WMS so their involvement is critical in testing, training and conversion.

A key mistake to avoid is an operations-heavy project team that lacks sufficient representation from your IT team.

Define realistic objectives and timeframes for achieving a positive ROI

When implementing a WMS the business case needs to be robust. The timeframe for delivering results must also take into account the software learning curve. Deployment times should be proposed and verified from research on similar projects, and executives must make an assessment based on a rational analysis of what needs to be done. Appropriate staff members must be recruited into projects and executives must agree on a realistic timeframe for delivering a positive ROI.

Once you’ve chosen the right WMS solution, supply chain executives have to define the various needs and objectives of different stakeholders and need to set out what they might require from them. One of the best ways to establish these needs is to run an executive workshop led by an experienced facilitator. The facilitator helps produce a vision of the project, along with broad goals, which together define the path ahead. This enables the team to create processes and detailed action plans to meet business goals.

Identify and use best practice

Adopting best practices recommended by your software provider is a quick way to bring significant benefits and enable process improvement changes that would otherwise be unattainable.

Once you’ve chosen the right supplier, they should be able to advise you on how to develop an implementation strategy which seeks to unearth process improvements by considering time, cost, functionality and risk. This route should provide an established system of project management that facilitates a clear analysis of a company's operations and distribution channels.

Subsequently, this identifies the steps necessary to improve processes that deliver operational efficiency improvements and facilitate growth.

Clearly define and design your business process requirements prior to the project.

The project should never compromise on the effort required in the Design phase. Additional effort to ensure the Design is correct while utilising the best qualities of the system will not only save time and money later in the project but will deliver real business benefit sooner.

Master data

The more robust, accurate and structured your approach to master data management and its integrity, the higher your chances of success will be. In addition, if you have a focus on master data you will be able to utilize more functionality and achieve more from your WMS in the short, medium and long-term as many of the core configurations are driven by the availability and quality of the master data.

Check out our Mater Data Checklist to ensure a successful WMS implementation that focuses primarily on what warehouse master data is and why it matters.

The Integration process

A robust and tested technical architecture based on an accepted and “best of breed” integration platform is critical. Despite having a class-leading ERP and Best of Breed WMS, the entire solution is technically dependent on the ability of systems to be integrated seamlessly, and whilst this typically isn’t an issue with today’s systems, it requires careful planning, execution and exception planning.

The testing process

Testing takes in four phases – system testing, integration testing, user acceptance and volume testing.

- System testing ensures the system has been configured correctly to support defined business processes.

- Integration testing is when the system is plugged into your company's existing systems and external supplier or customer's systems, which will make sure they all work together seamlessly.

- User-acceptance involves 'super-users' – operational staff who will be the heaviest users of the system – and getting their buy-in that the system is fit for purpose.

In each testing phase, companies should use actual data that represents your live business environment, involve real users and adhere to established business processes. Project managers should not underestimate the importance of volume testing. This is the 'stressful' part of this phase but is vital to the success of your WMS implementation.

Train users

Executives should also make sure users understand the importance of following the standard operating procedures, and that SOPs are clearly documented (with use of screenshots and non-system-related processes that users also need to follow).

It’s a good idea to ensure that the training skills required for bringing future system users up to speed are transferred to your organisation. Training an internal trainer will minimise long-term reliance on your vendor for all your additional training needs.

Communicate effectively and aim for a series of quick wins

In a climate where results are the watchword, your team should plan to deliver a series of quick wins and a small, but achievable series of significant and tangible benefits within the first twelve months so they can quickly demonstrate value to the business. A bigger ROI will take longer, but this helps garner support from executives eager to see that progress is being made.

The go-live process

-

-

Timing – where possible, the go-live should coincide with a slower trading period for your business. If there are issues there will be less of an impact

-

Volume Planning – where possible, try to pull inbound and outbound order volumes forward so that you can reduce the flow of goods for the first few days/ week of the implementation. This will reduce pressure on your operation as they adapt to the WMS

-

Go Live Support – plan to have your project team on site and working directly with the functional users on the floor until such time as there is a transition of skill and the operational teams are comfortable and take responsibility for the process and level 1 support issues

-

What happens after the implementation?

After the implementation, it’s even more critical to plan appropriately when, for example, project teams are partly disassembled, or key project team members leave the business. People who know how to address impending issues, which may be a threat to the business, will need to be available.

For the long-term, companies need to have established a team made up of individuals who worked on the project, as well as stakeholders from other functional areas within the business. Collectively they should have a responsibility to periodically assess risks (and the probability of those scenarios occurring), to prepare for those risks and ensure that continued optimisation of the WMS and the processes it supports are in place.

The key to a successful implementation, over the short, medium and long-term, is having quality people (and enough of them) and dedicating sufficient time to complete the project. Your team needs to be able to communicate effectively, both internally and externally, with suppliers and clients throughout the pre- and post- implementation phases.

These tactics all point to the importance of the pre-selection approach and preparation, and how transforming this into operational execution plays a critical role in delivering the benefits promised by a warehouse management system.

When business operations embrace and internalise the changes associated with supply chain process improvements, the effective and long-term use of a WMS will deliver significant benefits. When your focus is on meticulous execution, ongoing risk monitoring and a well-orchestrated implementation driven by skilled program managers, superior business benefits and a positive and measurable ROI are achievable.

Quick Contact

Fill out the form below to get in touch